The Role of Cantilever Racks in Protecting Delicate and Heavy Loads

Cantilever racks are specialized storage solutions designed to handle both delicate and heavy loads with precision and care. Unlike conventional storage systems, cantilever racks offer a unique approach that combines strength with sensitivity, making them indispensable in modern warehousing environments. These racks are particularly valuable in industries where the preservation of items is paramount, such as pharmaceuticals, electronics, and fine arts. By providing a secure and efficient storage solution, cantilever racks have become a cornerstone of organized inventory management.

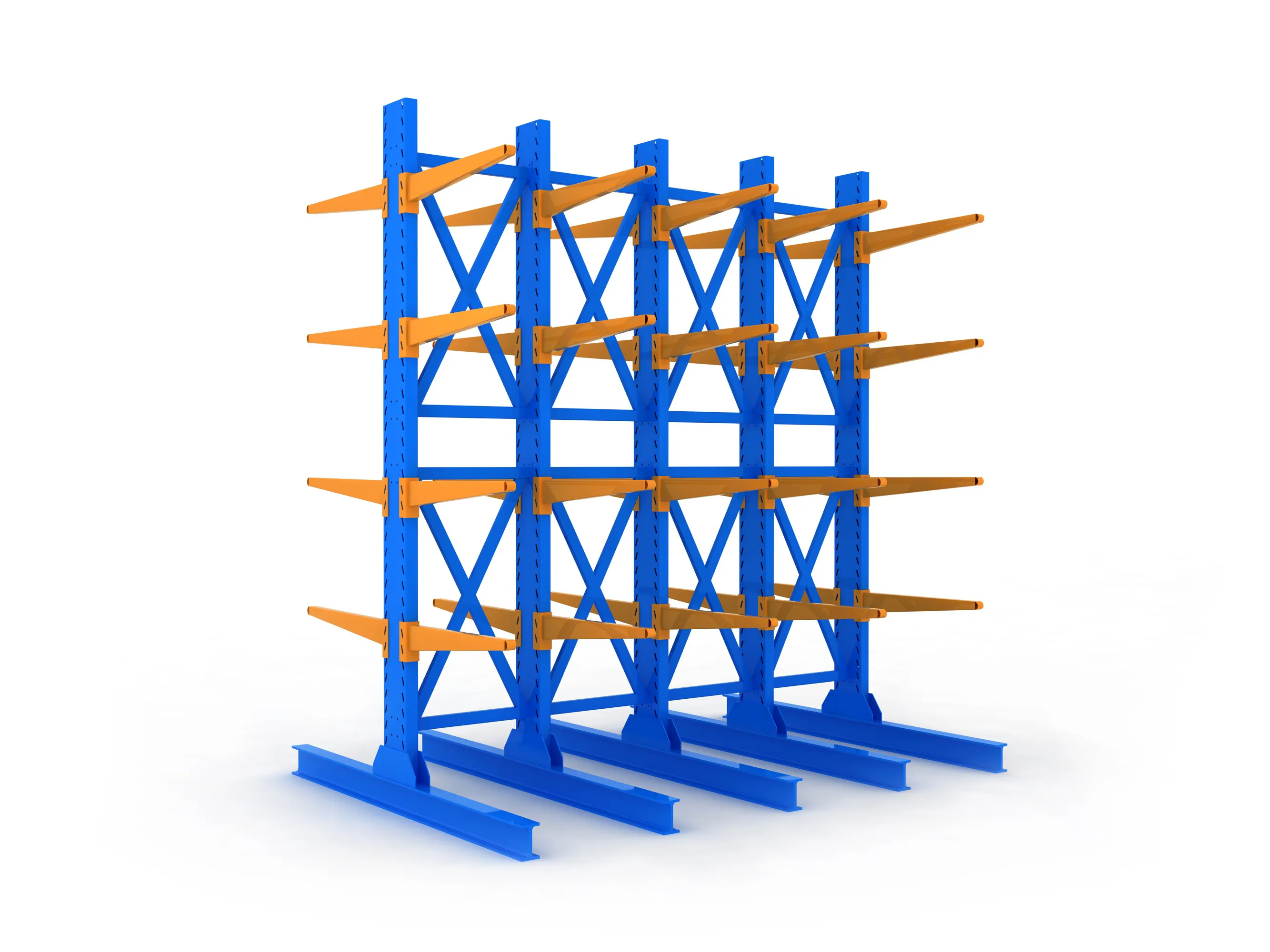

Design and Construction of Cantilever Racks

The design and construction of cantilever racks are rooted in engineering excellence, ensuring durability and stability. These racks are typically constructed from robust materials like steel, which offer both strength and flexibility. The structural integrity is enhanced through a balanced use of horizontal and vertical beams, creating a sturdy foundation that can withstand significant weight. Proper construction techniques, including precise alignment and secure fastenings, ensure that the racks remain stable under various conditions. The design not only maximizes load capacity but also minimizes the risk of deformation or sagging, making them suitable for both heavy and delicate items.

Benefits of Using Cantilever Racks for Delicate Goods

One of the most significant advantages of cantilever racks is their ability to protect delicate goods from harm. By minimizing handling, these racks reduce the risk of shock and vibration, which can be detrimental to sensitive items. The adjustable shelves within the racks allow for precise positioning, ensuring that items are stored evenly and securely. Additionally, many cantilever racks are coated with protective materials to shield against moisture, dust, and other environmental factors. This combination of features ensures that items remain in optimal condition, whether stored for short or long periods.

Effective Management of Heavy Loads with Cantilever Racks

While their primary role is to protect delicate goods, cantilever racks are equally effective in managing heavy loads. These racks are designed to distribute weight evenly across their structure, preventing sagging or uneven load distribution that could compromise stability. The modular design allows for customization, accommodating a wide range of load sizes and shapes. Whether storing large machinery components or heavy amassed items, cantilever racks provide a reliable solution. Their construction ensures that even under significant weight, the racks maintain their structural integrity, offering a durable and efficient storage solution.

Real-World Applications and Success Stories

The success of cantilever racks is evident in numerous real-world applications. In the automotive industry, these racks are commonly used to store sensitive components such as engine parts and electronic control units. Their protective features and efficient design have significantly reduced the risk of damage during storage. Similarly, in the pharmaceutical sector, cantilever racks are employed to store delicate medications and reagents, ensuring their integrity throughout the storage process. Case studies also highlight their use in aerospace, where cantilever racks have been instrumental in safely storing and transporting high-value components. These examples underscore the versatility and effectiveness of cantilever racks across diverse industries.

Comparative Analysis: Cantilever Racks vs. Traditional Storage Solutions

When compared to traditional storage solutions like flow racks or pallet racks, cantilever racks offer distinct advantages. While flow racks provide quick access and easy cleaning, they may not offer the same level of protection for delicate items. Pallet racks, on the other hand, are excellent for heavier goods but may struggle with precise positioning of lighter items. Cantilever racks, with their adjustable shelves and protective design, provide a balanced solution that caters to both delicate and heavy loads. Their modular construction and customizable features further enhance their versatility, making them a superior choice for modern storage needs.

Maintenance and Long-Term Use of Cantilever Racks

Proper maintenance is crucial to ensuring the longevity and efficiency of cantilever racks. Regular inspections and cleaning are essential to maintain their structural integrity and protective coatings. Environmental factors such as humidity and temperature fluctuations can impact the performance of these racks, so awareness and preventive measures are vital. By implementing a routine maintenance schedule, businesses can extend the life of their cantilever racks and ensure they remain a reliable part of their inventory management system.

Why Cantilever Racks Are Essential for Safeguarding Loads

In conclusion, cantilever racks play a vital role in safeguarding both delicate and heavy loads. Their design, construction, and features make them an indispensable tool in modern warehousing. Whether in automotive, pharmaceutical, or aerospace industries, these racks provide a secure and efficient solution for storage. By adopting cantilever racks, businesses can enhance the safety and integrity of their inventory, leading to improved operational efficiency. As technology continues to evolve, the importance of cantilever racks only grows, making them a must-have for any organized storage environment. Cantilever racks are not just storage solutions; they are critical investments in the future of any warehousing operation.